Array

(

[id] => 4077

[site_id] => 1

[project_id] => 478

[cate_id] => 793

[thumb] => Array

(

[id] => 3682

[cate_id] => 1

[folder] => res/202307/07/

[name] => 92e9db3004164440.jpg

[ext] => jpg

[filename] => res/202307/07/92e9db3004164440.jpg

[ico] => res/_cache/_ico/36/3682.jpg

[addtime] => 1688724355

[title] => Largeozone-generator

[attr] => Array

(

[width] => 500

[height] => 400

)

[note] =>

[session_id] =>

[user_id] => 0

[download] => 0

[admin_id] => 1

[mime_type] => image/jpeg

[gd] => Array

(

[auto] => res/_cache/auto/36/3682.jpg

[thumb] => res/_cache/thumb/36/3682.jpg

)

)

[content] => The ozone generator for sewage treatment uses an oxygen production system or liquid oxygen as the gas source. The ozone concentration is as high as 80-120mg/L. It can pre-oxidize and deep-oxidize various domestic sewage, industrial wastewater, agricultural sewage and medical wastewater. Disinfection, sterilization, decolorization, deodorization, COD reduction, etc.

The raw materials for ozone production are divided into three types: air, pure oxygen, and liquid oxygen. The ozone concentration obtained by using dry air to produce ozone is generally 1% to 3%; while the ozone concentration produced by using pure oxygen or liquid oxygen can reach about 10%, and the power consumption of air to produce ozone is about the other two methods 2 times.

Oxidation and disinfection characteristics of ozone generator:

①[**]s an efficient and non-secondary pollution oxidizing agent, ozone has the strongest oxidizing ability among common oxidizing agents, and its oxidizing ability is twice that of chlorine.

②Ozone disinfection is less affected by pH value, water temperature and ammonia content in water.

③Ozone removes the smell and taste of microorganisms, aquatic plants, algae and other organic matter, and the effect is good. The decolorization ability is more effective and rapid than Cl2 and ClO2.

④ [**]dding ozone can change the nature and size of the surface charge of small particles, and make the charged particles aggregate; at the same time, in the process of oxidizing dissolved organic matter in the ozone generator, there is also "microflocculation", which is helpful for improving the coagulation effect. Certain effect.

⑤ Ozone has a good disinfection effect, small dosage, fast action, no harmful substances such as chloroform, and can also make water have better sensory indicators.

⑥Ozone can chlorinate and decompose macromolecular organic matter that is not easy to degrade in water into small molecular organic matter, and oxygenate water to increase dissolved oxygen in water, which provides better conditions for subsequent treatment (especially biological treatment).

The operating conditions of the ozone generator for sewage treatment depend on the type of industry and the type of wastewater. These operating processes can be categorized by family:

1) The entire treatment process (pure chemical process, chemical, biological and chemical, biological, physical combined process)

2) [**]pplication (indoor pretreatment for water recycling, or water discharged from users indirectly to public water treatment facilities, and water treatment at the end of the pipe network for direct discharge to rivers and bays)

3) Removal of compounds (oxidative transformation of toxic or colored substances, reduction of comprehensive parameters (DOC or COD), disinfection or removal of particulate matter) throughout the treatment process (pure chemical process, chemical/biological and chemical/biological/physical combined process).

Usually, the combined process of ozone oxidation and biodegradable process or the use of advanced oxidation technology ([**]OPS) to improve the efficiency of oxidation (such as O3/H2O2) can reduce the amount of ozone and operating costs. [**]t present, in most cases, the ozone oxidation unit of wastewater is placed before the chemical oxidation in the biodegradation system, and sometimes it is also placed after the chemical oxidation treatment unit (ie O3-biological treatment-O3 system).

In industrial applications, a combination of ozone oxidation and biodegradation processes is usually used, which can reduce ozone consumption and operating costs. The most commonly used gas-liquid contactors in industrial wastewater ozonation systems are bubble column reactors equipped with diffusers or Venturi injectors, most of which operate in series countercurrent mode. Many reactors are operated under pressurized conditions in order to achieve higher ozone mass transfer rates, which in turn increases the efficiency of the overall process.

[**]pplication scope of ozone generator for sewage treatment:

1. Industrial cooling water treatment

2. Various industrial production wastewater treatment

3. [**]quaculture water treatment

4. Pipeline direct drinking water treatment

5. Medical wastewater treatment

6. Wastewater treatment in slaughtering and processing plants

7. Urban domestic sewage treatment

Physical and chemical properties of ozone Ozone is a blue gas at room temperature. It has a pungent special smell; it is blue-black in liquid state, with a melting point of -192.5±0.4°C=(760mmH koji, a boiling point of -111.9+0.3°Cc760mml-I koji, a gas density of 21-44g/L, and a solubility of 0.68g/L I_., the solubility coefficient is 032. Theoretically, the solubility of ozone decreases with the increase of temperature. Its maximum absorption wavelength to ultraviolet light is 254nm, and the maximum concentration TCV≤0.1 allowed in the working environment. Ozone is a kind of strong oxidant, vapor The reduction potential of Ozone is -2.07V in acidic medium and -124V in alkaline medium. The decomposition speed of ozone in water is very fast. It can quickly return to the state of oxygen in aqueous solution containing impurities, and its lifetime is 5- 30rain. If the water temperature is close to 0°C, it will be more stable. Studies have shown that the decomposition rate of ozone in water increases with the increase of water temperature and pH value. Because ozone has strong oxidizing properties, it can react with all metals except gold and platinum. It reacts and can oxidize many organic substances. It is very easy to react with -SH, =s, -NH, =NH, -OH and -CHO, etc.; it can also react with aromatic compounds. But the speed is slower: almost no for aliphatic compounds Effect. Based on the reason that ozone can oxidize metals, in actual production, ferrochromium alloys containing 25% are often used to manufacture ozone generating equipment. Moreover, common rubber cannot be used as sealing materials in generating equipment and metering equipment, and resistant Corrosion of silicone or acid-resistant rubber.

1: Disinfection and advanced treatment of drinking water The application of ozone in drinking water has a history of 100 years, as early as 1893. The Netherlands established the world's first ozone treatment device for drinking water. Disinfection of RJ Que River water . The treatment of drinking water must not only be able to effectively disinfect and sterilize bacteria, but also must remove micro-pollutants. Oxygen or sodium hypochlorite are mostly used as disinfectants and oxidants in traditional drinking water treatment processes. Chlorine can effectively kill bacteria in water. However, in recent years, it has been found that some by-products produced by chlorine treatment, such as chloroform and other organic halogenated substances, have certain toxicity, and even have carcinogenic, teratogenic, and mutagenic effects. For this reason, the ozone treatment technology of drinking water has been paid attention to and studied deeply. Studies have shown that ozone not only has a strong disinfection and sterilization effect, but also can oxidize and remove micro-pollutants in water. These micro-pollutants are often difficult to biodegrade, such as humic acid, pesticides, and chlorinated organic substances. [**]nd ozone oxidation is more thorough. Less by-products are produced.

2: Deodorization and decolorization of water bodies The organic or inorganic substances in wastewater containing sulfur and nitrogen are the main causes of odor. When 1-2mg/L low concentration of ozone is added to wastewater. These substances can be oxidized to achieve a deodorizing effect. It is worth mentioning that the ozone has been used to remove the odor. It can also prevent the recurrence of the odor. This is because the gas produced by the ozone generator contains a large amount of oxygen or air, and the odor-generating substances are easy to cause odor in an oxygen-deficient environment. Environment. It can prevent the reproduction of bad smell. Ozone can oxidize and decompose colored organic matter in water. [**] small amount of ozone can have a good effect. Colored organics are generally polycyclic organics with unsaturated bonds. When treated with ozone, the unsaturated chemical bonds can be opened to break the bonds of molecules, thus making the water clear. Basic research work on the decolorization of printing and dyeing wastewater by using ozone has been carried out in China.

3: [**]ustrian oxidation treatment of inorganic and organic pollutants in wastewater In the industrial wastewater, cyanide-containing wastewater and typhol wastewater were first treated by ozonation. The toxicity of cyanate produced by the oxidation of chloride by ozone is only about 1/100 of that of cyanide, and it can even be further oxidized into harmless substances. It is more difficult to treat ferricyanide chromium salt with ozone, but it can promote the decomposition of ozone to cyanide for copper ions with other chromium cyanide content. Ozone can also be used to treat wastewater containing metal ions, oxidizing metal ions present in wastewater into water-insoluble compounds. Ozone can react with various organic compounds or functional groups. Such as c=c, c thatch c, aromatic compounds, heterocyclic compounds, N=N, c; N, one OI-l, one SH, one NH2, one cH, etc. . The role of ozone in destroying and removing pollutants from wastewater has been extensively studied. Some studies have also been carried out on the products of ozonation of organic matter. The products of ozonation are mainly small organic molecules such as monoaldehydes, dialdehydes, aldehyde acids, monocarboxylic acids, and dicarboxylic acids. 3.4 [**]pplication of Ozone in Cooling Water Treatment Ozone has the effects of sterilization, corrosion inhibition and scale inhibition. It can replace the traditional chemical agent treatment to circulate cooling water, and the treatment cost is lower than the chemical agent treatment method, and there is no secondary pollution problem after treatment . Since the late 1970s, the United States began to study the treatment of cooling water by ozone, and it has been successfully used in more than 130 cooling towers. The maximum circulating water volume is 1000m/h. The operation is good. It should be noted that the prevention of corrosion and biofouling mainly depends on the chemical properties of the water in the system. Ozone treatment can effectively prevent corrosion and biofouling, but it should not be too dependent on ozone treatment. Pay attention to changes in water quality.

4: Conclusion The development of ozone technology has a history of many years,

It has also been widely studied and applied in water treatment. With the development of science and technology, the improvement of power supply, dielectric material, gas source preparation and control, detection and many other aspects related to the ozone generator will effectively increase the production of ozone and reduce energy consumption. [**]t the same time, there will be new breakthroughs and progress in the research on ozone in water treatment. I want to believe that large-scale ozone generators will be widely used in my country's water treatment industry, bringing health and cleanliness to society.

Equipment technical characteristics

1. The ozone generator is composed of a stainless steel frame shell, a high-frequency high-voltage power supply for the ozone generator, an electronic control configuration, an axial fan, and other parts.

2. The overall surface of the equipment is beautiful and stable.

3. The core components of the ozone generator adopt technologies such as medium positive electrode and alloy material covering, and the surface is covered with anti-corrosion and moisture-proof coating. It produces a large amount of ozone and operates stably. Under normal circumstances, the service life is as long as 5-8 years.

4. Core technology, high cost performance: This type of ozone generator uses a high-frequency power supply system to make oxygen molecules in or around the electric field electrochemically react to produce ozone. The ozone generator has the advantages of mature technology, stable work, long service life, large ozone output (etc., it is the most widely used ozone generator in related industries at home and abroad

5. Water-cooled generation tube and wind-cooled power supply: When the ozone generator is working, it will generate a lot of heat energy and needs to be cooled, otherwise the ozone will be decomposed while being generated due to high temperature. The water-cooled generator has good cooling effect, stable operation, no ozone attenuation, and can work continuously for a long time

6. [**]dopt quartz tube discharge technology: Quartz tube is most often used by some high-performance ozone generators because of its high dielectric constant, uniform wall thickness, good ellipticity, high temperature resistance, and humidity resistance. Ceramic plates are brittle and are only suitable for some small generators. The wall thickness and ellipticity of the ceramic tube are not easy to control, and it is prone to the problem of uneven discharge, so it is not used much. Glass tubes and enamel tubes have low dielectric constant, poor high temperature resistance, and are easy to burst, so they are only used in some low-end generators.

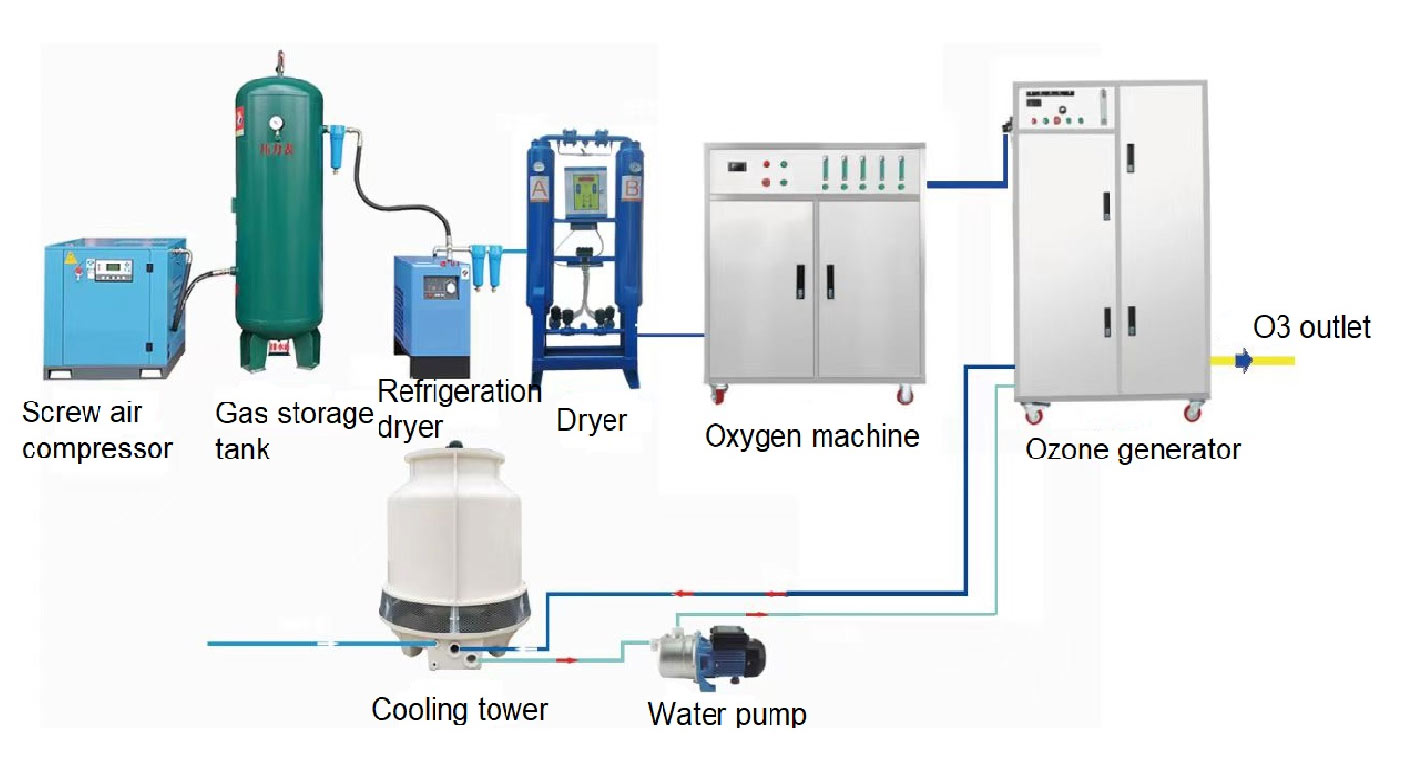

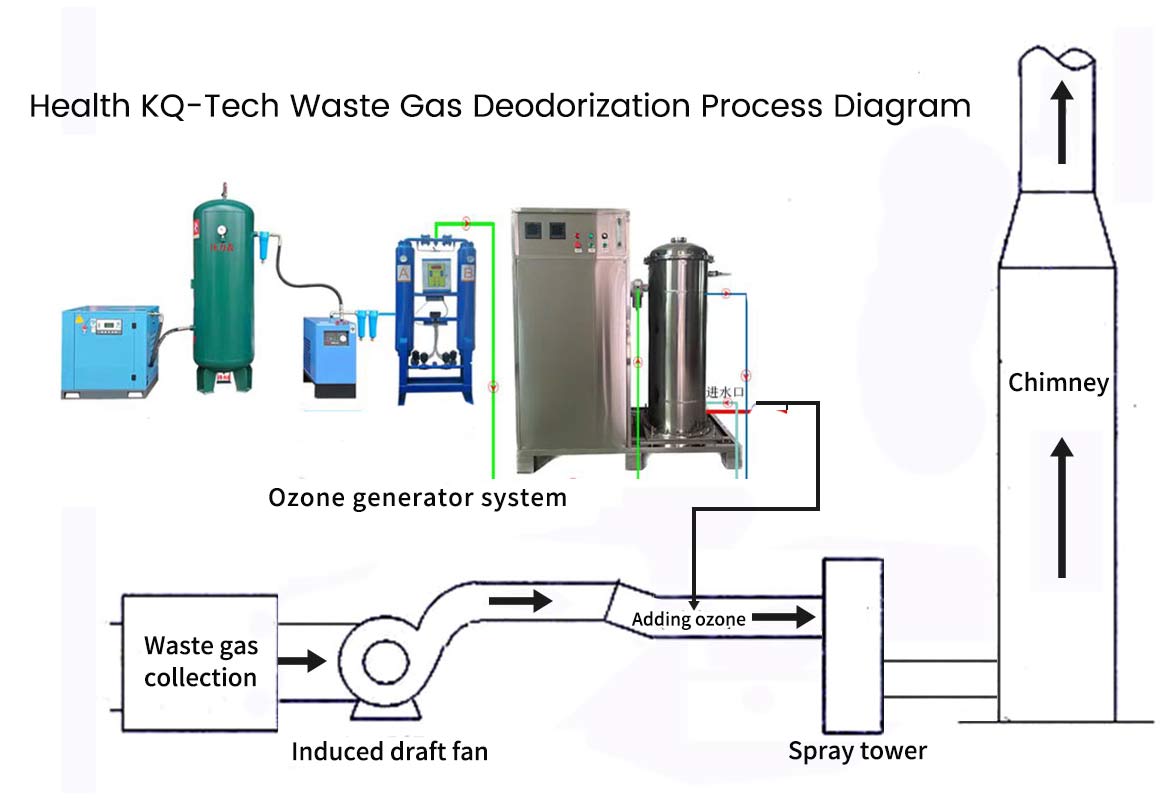

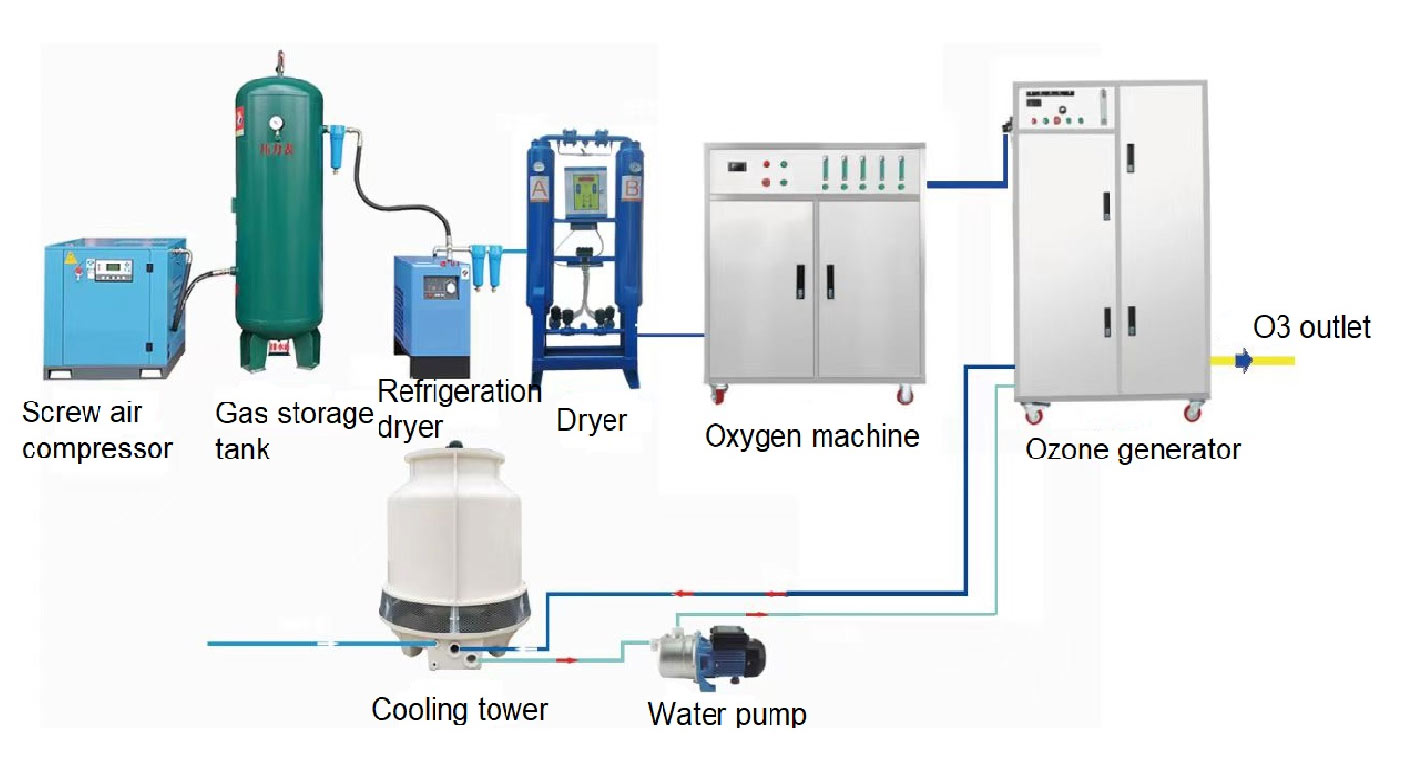

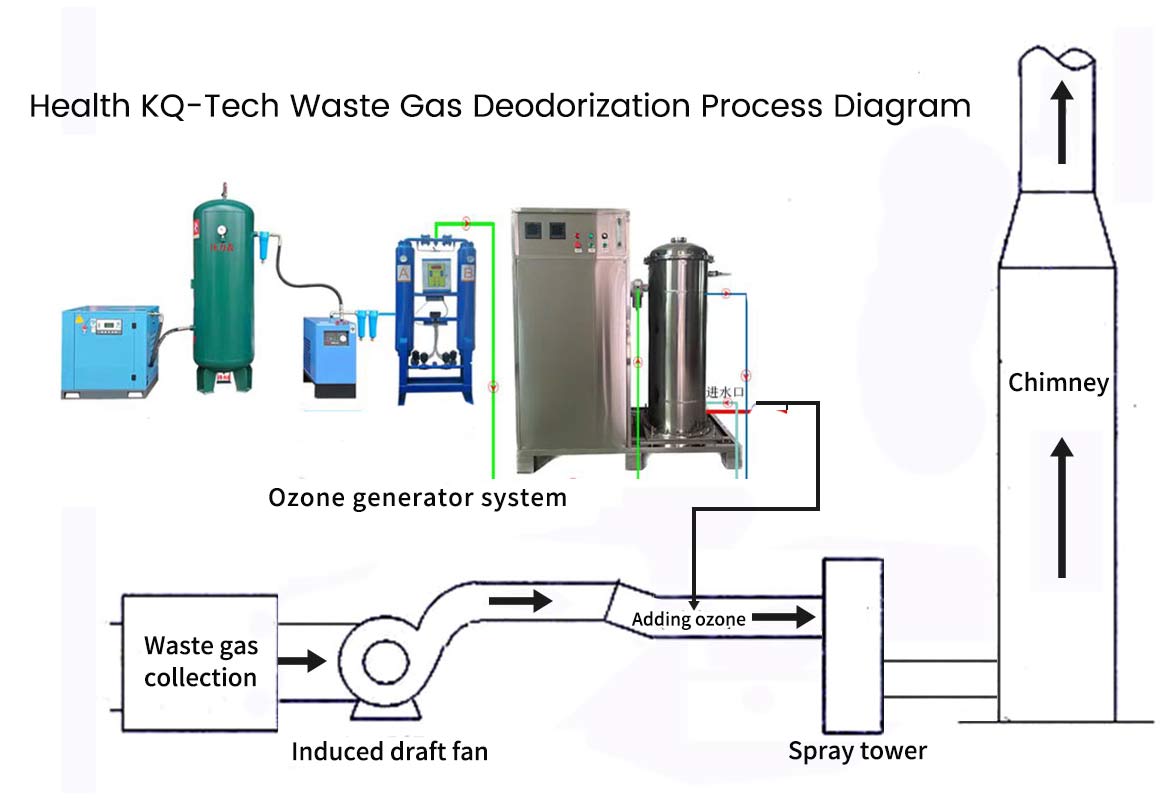

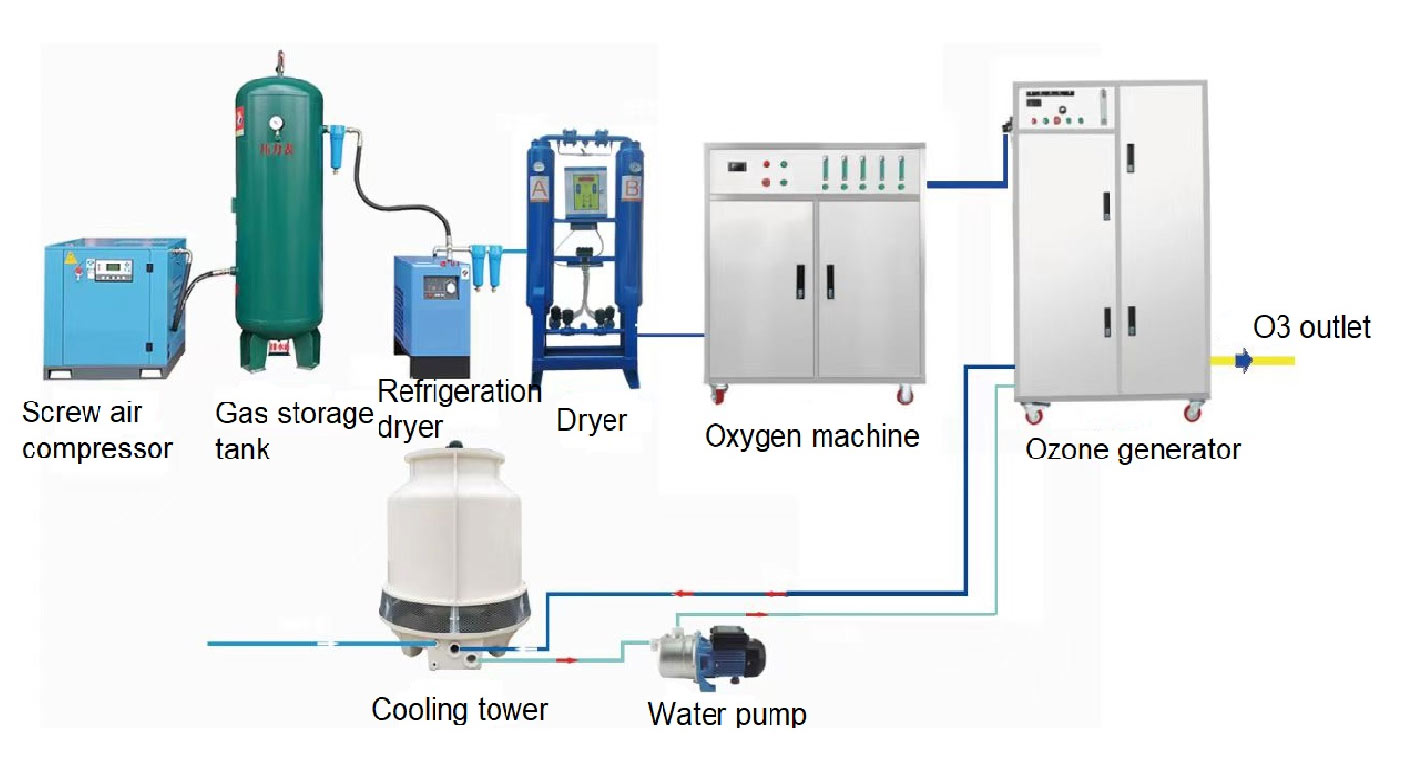

Complete system of large sewage ozone machine

3.1 Composition of ozone system

The ozone system is mainly composed of an ozone generator, a gas source system, and a control system. The ozone generator includes two parts: the ozone generating device (ozone discharge chamber) and the ozone power supply device; the air source system includes air compressors, freeze dryers, adsorption dryers or oxygen generators, air filters, etc.; ozone concentration detection Devices and other peripheral equipment can be equipped according to the needs of the buyer.

The air treatment system consists of air compressor, refrigerated dryer, adsorption dryer or oxygen generator, oil-water separator, and air filter to provide a qualified air source for the ozone generator. The air compressor adopts screw type air compressor, which has high air output efficiency, low noise and low operating cost. The air storage tank is used to store and buffer the compressed air provided by the air compressor in advance, and to make the pressure of the compressed air given by the air compressor constant and the air flow constant, so as to ensure the use conditions of the downstream purification equipment. The refrigerated dryer cools and condenses the compressed air under saturated conditions to remove water. Under normal working conditions, it can remove about 80% of the moisture in the compressed air. It has a large amount of water removal and low energy consumption. It belongs to shallow water removal and must be dried [**]nd cooperate to meet the ozone discharge requirements. [**]dsorption dryer is a dehumidification and purification device that uses the principle of pressure swing adsorption and heatless regeneration method to dry compressed air. It belongs to deep dehydration, and the air source can reach the atmospheric dew point -50 ℃ or so. Filters include main pipeline filtration, oil removal filtration, dust removal filtration, etc., to ensure that the oil content of the air source entering the adsorption dryer is less than 0.01mg/m3, and that the dust particle size of the air source entering the ozone generator is less than 1μm or even 0.01μm.

The qualified raw material gas source is decompressed by the pressure reducing valve, and the dew point meter monitors the dew point of the intake air online, and then enters the ozone discharge chamber after passing through the valve, and the pressure gauge and temperature gauge display the intake pressure and temperature on site. In the medium-frequency high-voltage electric field in the ozone discharge chamber, part of the oxygen turns into ozone, and the product gas is ozonated gas. [**]fter being monitored by pressure, temperature and flow, it enters the contact pool or oxidation tower. [**] microporous aeration pan is arranged inside the contact tank (or oxidation tower), and ozone gas is injected into the water body through the microporous aeration pan.

The control system adopts PLC to connect with the industrial control level computer. The ozone generator adopts the international advanced intermediate frequency discharge technology. It is equipped with CPU core control inside. The function of soft start and soft unloading is designed, and the feeding of the ozone generator can be adjusted linearly and smoothly. Power, to achieve 10%-100% adjustment of ozone production, to minimize the demand side's operating costs.

[**]n ozone leakage alarm device is installed in the ozone preparation room. When the ozone leakage in the environment in the preparation room exceeds the standard, the system will output an alarm, start the exhaust fan or stop the machine according to the detection signal.

The exhaust gas destroyer decomposes ozone by means of heating and catalysis, and the control of the entire exhaust gas destroyer is controlled by the exhaust gas destruction box. The ozone concentration of the decomposed gas is less than 0.16mg/m3, which can be directly discharged into the atmosphere.

[parent_id] => 0

[module_id] => 114

[title] => Large-scale ozone generator used in sewage treatment industry

[dateline] => 1688724336

[lastdate] => 1688724418

[sort] => 0

[status] => 1

[hidden] => 0

[hits] => 1889

[tpl] =>

[seo_title] => Large-scale ozone generator used in sewage treatment industry

[seo_keywords] => Large-scale ozone generator

[seo_desc] => The ozone generator for sewage treatment uses an oxygen production system or liquid oxygen as the gas source. The ozone concentration is as high as 80-120mg/L. It can pre-oxidize and deep-oxidize various domestic sewage, industrial wastewater, agricultura

[tag] => Array

(

[0] => Array

(

[id] => 35

[site_id] => 1

[identifier] =>

[title] => ozone water treatment

[url] => https://healthept.com/tag/35

[target] => _self

[hits] => 1533

[alt] => ozone water treatment

[is_global] => 0

[replace_count] => 0

[seo_title] =>

[seo_keywords] =>

[seo_desc] =>

[tpl] =>

[title_id] => c793

[html] => ozone water treatment

)

[1] => Array

(

[id] => 100

[site_id] => 1

[identifier] =>

[title] => Water treatment case

[url] => https://healthept.com/tag/100

[target] => _self

[hits] => 1708

[alt] => Water treatment case

[is_global] => 0

[replace_count] => 0

[seo_title] =>

[seo_keywords] =>

[seo_desc] =>

[tpl] =>

[title_id] => c793

[html] => Water treatment case

)

[2] => Array

(

[id] => 101

[site_id] => 1

[identifier] =>

[title] => ozone case

[url] => https://healthept.com/tag/101

[target] => _self

[hits] => 1682

[alt] => ozone case

[is_global] => 0

[replace_count] => 0

[seo_title] =>

[seo_keywords] =>

[seo_desc] =>

[tpl] =>

[title_id] => c793

[html] => ozone case

)

)

[attr] =>

[replydate] => 0

[user_id] => 0

[identifier] =>

[integral] => 0

[style] =>

[url] => https://healthept.com/4077.html

[_catelist] => Array

(

[793] => Array

(

[id] => 793

[site_id] => 1

[parent_id] => 736

[status] => 1

[title] => Water treatment

[taxis] => 10

[tpl_list] =>

[tpl_content] =>

[psize] => 0

[seo_title] => Ozone Water treatment case article

[seo_keywords] => Ozone Water treatment , Water treatment case,Ozone Water treatment article

[seo_desc] => Share more articles about ozone, oxygen production, farms, sewage water treatment cases.KQ Environmental Tech shares useful articles and blogs related to Ozone water treatment.

[identifier] => water-treatment

[tag] => Ozone Water treatment , Water treatment case, ozone case

[style] =>

[module_id] => 0

[psize_api] => 0

[url] => https://healthept.com/Case/water-treatment.html

)

)

)

The ozone generator for sewage treatment uses an oxygen production system or liquid oxygen as the gas source. The ozone concentration is as high as 80-120mg/L. It can pre-oxidize and deep-oxidize various domestic sewage, industrial wastewater, agricultural sewage and medical wastewater. Disinfection, sterilization, decolorization, deodorization, COD reduction, etc.

The raw materials for ozone production are divided into three types: air, pure oxygen, and liquid oxygen. The ozone concentration obtained by using dry air to produce ozone is generally 1% to 3%; while the ozone concentration produced by using pure oxygen or liquid oxygen can reach about 10%, and the power consumption of air to produce ozone is about the other two methods 2 times.

Oxidation and disinfection characteristics of ozone generator:

①[**]s an efficient and non-secondary pollution oxidizing agent, ozone has the strongest oxidizing ability among common oxidizing agents, and its oxidizing ability is twice that of chlorine.

②Ozone disinfection is less affected by pH value, water temperature and ammonia content in water.

③Ozone removes the smell and taste of microorganisms, aquatic plants, algae and other organic matter, and the effect is good. The decolorization ability is more effective and rapid than Cl2 and ClO2.

④ [**]dding ozone can change the nature and size of the surface charge of small particles, and make the charged particles aggregate; at the same time, in the process of oxidizing dissolved organic matter in the ozone generator, there is also "microflocculation", which is helpful for improving the coagulation effect. Certain effect.

⑤ Ozone has a good disinfection effect, small dosage, fast action, no harmful substances such as chloroform, and can also make water have better sensory indicators.

⑥Ozone can chlorinate and decompose macromolecular organic matter that is not easy to degrade in water into small molecular organic matter, and oxygenate water to increase dissolved oxygen in water, which provides better conditions for subsequent treatment (especially biological treatment).

The operating conditions of the ozone generator for sewage treatment depend on the type of industry and the type of wastewater. These operating processes can be categorized by family:

1) The entire treatment process (pure chemical process, chemical, biological and chemical, biological, physical combined process)

2) [**]pplication (indoor pretreatment for water recycling, or water discharged from users indirectly to public water treatment facilities, and water treatment at the end of the pipe network for direct discharge to rivers and bays)

3) Removal of compounds (oxidative transformation of toxic or colored substances, reduction of comprehensive parameters (DOC or COD), disinfection or removal of particulate matter) throughout the treatment process (pure chemical process, chemical/biological and chemical/biological/physical combined process).

Usually, the combined process of ozone oxidation and biodegradable process or the use of advanced oxidation technology ([**]OPS) to improve the efficiency of oxidation (such as O3/H2O2) can reduce the amount of ozone and operating costs. [**]t present, in most cases, the ozone oxidation unit of wastewater is placed before the chemical oxidation in the biodegradation system, and sometimes it is also placed after the chemical oxidation treatment unit (ie O3-biological treatment-O3 system).

In industrial applications, a combination of ozone oxidation and biodegradation processes is usually used, which can reduce ozone consumption and operating costs. The most commonly used gas-liquid contactors in industrial wastewater ozonation systems are bubble column reactors equipped with diffusers or Venturi injectors, most of which operate in series countercurrent mode. Many reactors are operated under pressurized conditions in order to achieve higher ozone mass transfer rates, which in turn increases the efficiency of the overall process.

[**]pplication scope of ozone generator for sewage treatment:

1. Industrial cooling water treatment

2. Various industrial production wastewater treatment

3. [**]quaculture water treatment

4. Pipeline direct drinking water treatment

5. Medical wastewater treatment

6. Wastewater treatment in slaughtering and processing plants

7. Urban domestic sewage treatment

Physical and chemical properties of ozone Ozone is a blue gas at room temperature. It has a pungent special smell; it is blue-black in liquid state, with a melting point of -192.5±0.4°C=(760mmH koji, a boiling point of -111.9+0.3°Cc760mml-I koji, a gas density of 21-44g/L, and a solubility of 0.68g/L I_., the solubility coefficient is 032. Theoretically, the solubility of ozone decreases with the increase of temperature. Its maximum absorption wavelength to ultraviolet light is 254nm, and the maximum concentration TCV≤0.1 allowed in the working environment. Ozone is a kind of strong oxidant, vapor The reduction potential of Ozone is -2.07V in acidic medium and -124V in alkaline medium. The decomposition speed of ozone in water is very fast. It can quickly return to the state of oxygen in aqueous solution containing impurities, and its lifetime is 5- 30rain. If the water temperature is close to 0°C, it will be more stable. Studies have shown that the decomposition rate of ozone in water increases with the increase of water temperature and pH value. Because ozone has strong oxidizing properties, it can react with all metals except gold and platinum. It reacts and can oxidize many organic substances. It is very easy to react with -SH, =s, -NH, =NH, -OH and -CHO, etc.; it can also react with aromatic compounds. But the speed is slower: almost no for aliphatic compounds Effect. Based on the reason that ozone can oxidize metals, in actual production, ferrochromium alloys containing 25% are often used to manufacture ozone generating equipment. Moreover, common rubber cannot be used as sealing materials in generating equipment and metering equipment, and resistant Corrosion of silicone or acid-resistant rubber.

1: Disinfection and advanced treatment of drinking water The application of ozone in drinking water has a history of 100 years, as early as 1893. The Netherlands established the world's first ozone treatment device for drinking water. Disinfection of RJ Que River water . The treatment of drinking water must not only be able to effectively disinfect and sterilize bacteria, but also must remove micro-pollutants. Oxygen or sodium hypochlorite are mostly used as disinfectants and oxidants in traditional drinking water treatment processes. Chlorine can effectively kill bacteria in water. However, in recent years, it has been found that some by-products produced by chlorine treatment, such as chloroform and other organic halogenated substances, have certain toxicity, and even have carcinogenic, teratogenic, and mutagenic effects. For this reason, the ozone treatment technology of drinking water has been paid attention to and studied deeply. Studies have shown that ozone not only has a strong disinfection and sterilization effect, but also can oxidize and remove micro-pollutants in water. These micro-pollutants are often difficult to biodegrade, such as humic acid, pesticides, and chlorinated organic substances. [**]nd ozone oxidation is more thorough. Less by-products are produced.

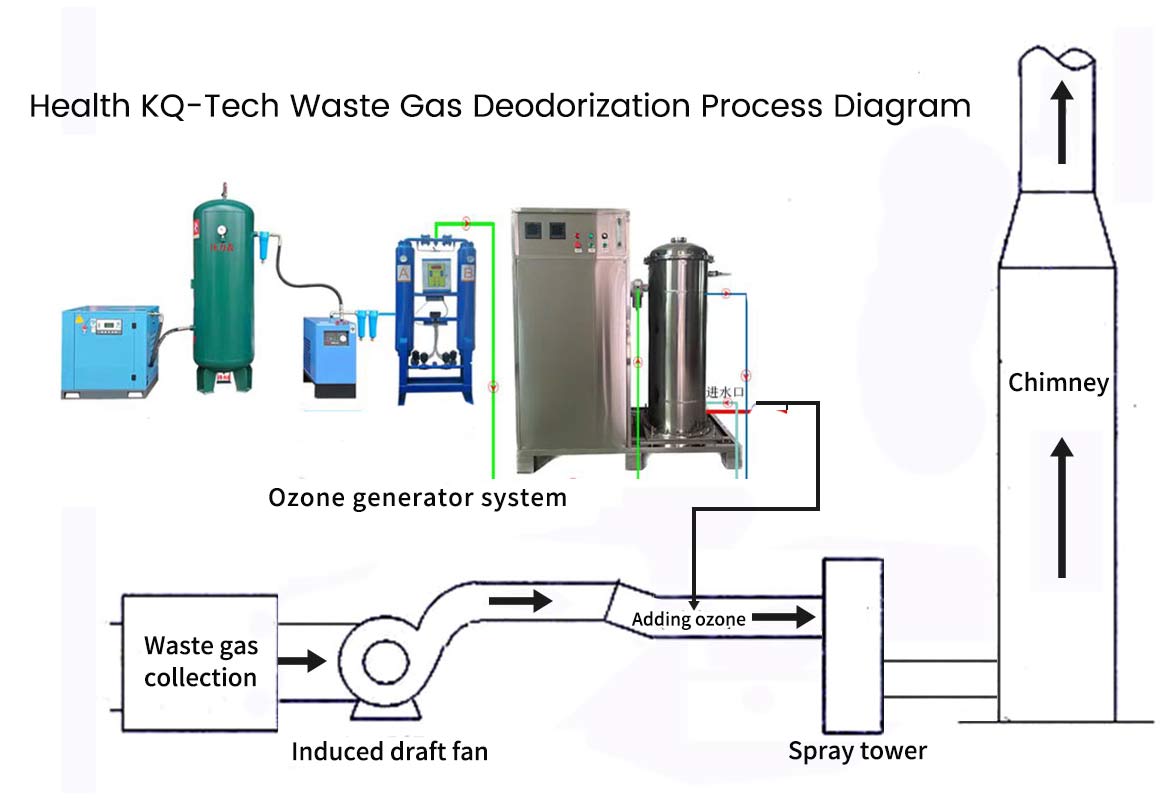

2: Deodorization and decolorization of water bodies The organic or inorganic substances in wastewater containing sulfur and nitrogen are the main causes of odor. When 1-2mg/L low concentration of ozone is added to wastewater. These substances can be oxidized to achieve a deodorizing effect. It is worth mentioning that the ozone has been used to remove the odor. It can also prevent the recurrence of the odor. This is because the gas produced by the ozone generator contains a large amount of oxygen or air, and the odor-generating substances are easy to cause odor in an oxygen-deficient environment. Environment. It can prevent the reproduction of bad smell. Ozone can oxidize and decompose colored organic matter in water. [**] small amount of ozone can have a good effect. Colored organics are generally polycyclic organics with unsaturated bonds. When treated with ozone, the unsaturated chemical bonds can be opened to break the bonds of molecules, thus making the water clear. Basic research work on the decolorization of printing and dyeing wastewater by using ozone has been carried out in China.

3: [**]ustrian oxidation treatment of inorganic and organic pollutants in wastewater In the industrial wastewater, cyanide-containing wastewater and typhol wastewater were first treated by ozonation. The toxicity of cyanate produced by the oxidation of chloride by ozone is only about 1/100 of that of cyanide, and it can even be further oxidized into harmless substances. It is more difficult to treat ferricyanide chromium salt with ozone, but it can promote the decomposition of ozone to cyanide for copper ions with other chromium cyanide content. Ozone can also be used to treat wastewater containing metal ions, oxidizing metal ions present in wastewater into water-insoluble compounds. Ozone can react with various organic compounds or functional groups. Such as c=c, c thatch c, aromatic compounds, heterocyclic compounds, N=N, c; N, one OI-l, one SH, one NH2, one cH, etc. . The role of ozone in destroying and removing pollutants from wastewater has been extensively studied. Some studies have also been carried out on the products of ozonation of organic matter. The products of ozonation are mainly small organic molecules such as monoaldehydes, dialdehydes, aldehyde acids, monocarboxylic acids, and dicarboxylic acids. 3.4 [**]pplication of Ozone in Cooling Water Treatment Ozone has the effects of sterilization, corrosion inhibition and scale inhibition. It can replace the traditional chemical agent treatment to circulate cooling water, and the treatment cost is lower than the chemical agent treatment method, and there is no secondary pollution problem after treatment . Since the late 1970s, the United States began to study the treatment of cooling water by ozone, and it has been successfully used in more than 130 cooling towers. The maximum circulating water volume is 1000m/h. The operation is good. It should be noted that the prevention of corrosion and biofouling mainly depends on the chemical properties of the water in the system. Ozone treatment can effectively prevent corrosion and biofouling, but it should not be too dependent on ozone treatment. Pay attention to changes in water quality.

4: Conclusion The development of ozone technology has a history of many years,

It has also been widely studied and applied in water treatment. With the development of science and technology, the improvement of power supply, dielectric material, gas source preparation and control, detection and many other aspects related to the ozone generator will effectively increase the production of ozone and reduce energy consumption. [**]t the same time, there will be new breakthroughs and progress in the research on ozone in water treatment. I want to believe that large-scale ozone generators will be widely used in my country's water treatment industry, bringing health and cleanliness to society.

Equipment technical characteristics

1. The ozone generator is composed of a stainless steel frame shell, a high-frequency high-voltage power supply for the ozone generator, an electronic control configuration, an axial fan, and other parts.

2. The overall surface of the equipment is beautiful and stable.

3. The core components of the ozone generator adopt technologies such as medium positive electrode and alloy material covering, and the surface is covered with anti-corrosion and moisture-proof coating. It produces a large amount of ozone and operates stably. Under normal circumstances, the service life is as long as 5-8 years.

4. Core technology, high cost performance: This type of ozone generator uses a high-frequency power supply system to make oxygen molecules in or around the electric field electrochemically react to produce ozone. The ozone generator has the advantages of mature technology, stable work, long service life, large ozone output (etc., it is the most widely used ozone generator in related industries at home and abroad

5. Water-cooled generation tube and wind-cooled power supply: When the ozone generator is working, it will generate a lot of heat energy and needs to be cooled, otherwise the ozone will be decomposed while being generated due to high temperature. The water-cooled generator has good cooling effect, stable operation, no ozone attenuation, and can work continuously for a long time

6. [**]dopt quartz tube discharge technology: Quartz tube is most often used by some high-performance ozone generators because of its high dielectric constant, uniform wall thickness, good ellipticity, high temperature resistance, and humidity resistance. Ceramic plates are brittle and are only suitable for some small generators. The wall thickness and ellipticity of the ceramic tube are not easy to control, and it is prone to the problem of uneven discharge, so it is not used much. Glass tubes and enamel tubes have low dielectric constant, poor high temperature resistance, and are easy to burst, so they are only used in some low-end generators.

Complete system of large sewage ozone machine

3.1 Composition of ozone system

The ozone system is mainly composed of an ozone generator, a gas source system, and a control system. The ozone generator includes two parts: the ozone generating device (ozone discharge chamber) and the ozone power supply device; the air source system includes air compressors, freeze dryers, adsorption dryers or oxygen generators, air filters, etc.; ozone concentration detection Devices and other peripheral equipment can be equipped according to the needs of the buyer.

The air treatment system consists of air compressor, refrigerated dryer, adsorption dryer or oxygen generator, oil-water separator, and air filter to provide a qualified air source for the ozone generator. The air compressor adopts screw type air compressor, which has high air output efficiency, low noise and low operating cost. The air storage tank is used to store and buffer the compressed air provided by the air compressor in advance, and to make the pressure of the compressed air given by the air compressor constant and the air flow constant, so as to ensure the use conditions of the downstream purification equipment. The refrigerated dryer cools and condenses the compressed air under saturated conditions to remove water. Under normal working conditions, it can remove about 80% of the moisture in the compressed air. It has a large amount of water removal and low energy consumption. It belongs to shallow water removal and must be dried [**]nd cooperate to meet the ozone discharge requirements. [**]dsorption dryer is a dehumidification and purification device that uses the principle of pressure swing adsorption and heatless regeneration method to dry compressed air. It belongs to deep dehydration, and the air source can reach the atmospheric dew point -50 ℃ or so. Filters include main pipeline filtration, oil removal filtration, dust removal filtration, etc., to ensure that the oil content of the air source entering the adsorption dryer is less than 0.01mg/m3, and that the dust particle size of the air source entering the ozone generator is less than 1μm or even 0.01μm.

The qualified raw material gas source is decompressed by the pressure reducing valve, and the dew point meter monitors the dew point of the intake air online, and then enters the ozone discharge chamber after passing through the valve, and the pressure gauge and temperature gauge display the intake pressure and temperature on site. In the medium-frequency high-voltage electric field in the ozone discharge chamber, part of the oxygen turns into ozone, and the product gas is ozonated gas. [**]fter being monitored by pressure, temperature and flow, it enters the contact pool or oxidation tower. [**] microporous aeration pan is arranged inside the contact tank (or oxidation tower), and ozone gas is injected into the water body through the microporous aeration pan.

The control system adopts PLC to connect with the industrial control level computer. The ozone generator adopts the international advanced intermediate frequency discharge technology. It is equipped with CPU core control inside. The function of soft start and soft unloading is designed, and the feeding of the ozone generator can be adjusted linearly and smoothly. Power, to achieve 10%-100% adjustment of ozone production, to minimize the demand side's operating costs.

[**]n ozone leakage alarm device is installed in the ozone preparation room. When the ozone leakage in the environment in the preparation room exceeds the standard, the system will output an alarm, start the exhaust fan or stop the machine according to the detection signal.

The exhaust gas destroyer decomposes ozone by means of heating and catalysis, and the control of the entire exhaust gas destroyer is controlled by the exhaust gas destruction box. The ozone concentration of the decomposed gas is less than 0.16mg/m3, which can be directly discharged into the atmosphere.