By making oxygen on site, you will be able to set the exact purity required for your application without having to pay unnecessary fees for over-specified oxygen.High-quality lithium molecular sieve

Higher adsorption rate and better stability.

Oxygen flow rate: 1-50L/MIN

Power: 3500W

Weight: 170KG

Size: Custom

Configuration: built-in oil-free air compressor, filter

Features:

1. Oxygen molecular sieve imported from France

2. Stable oxygen output

3. Low noise <65db

4. Oxygen concentration 93+3%

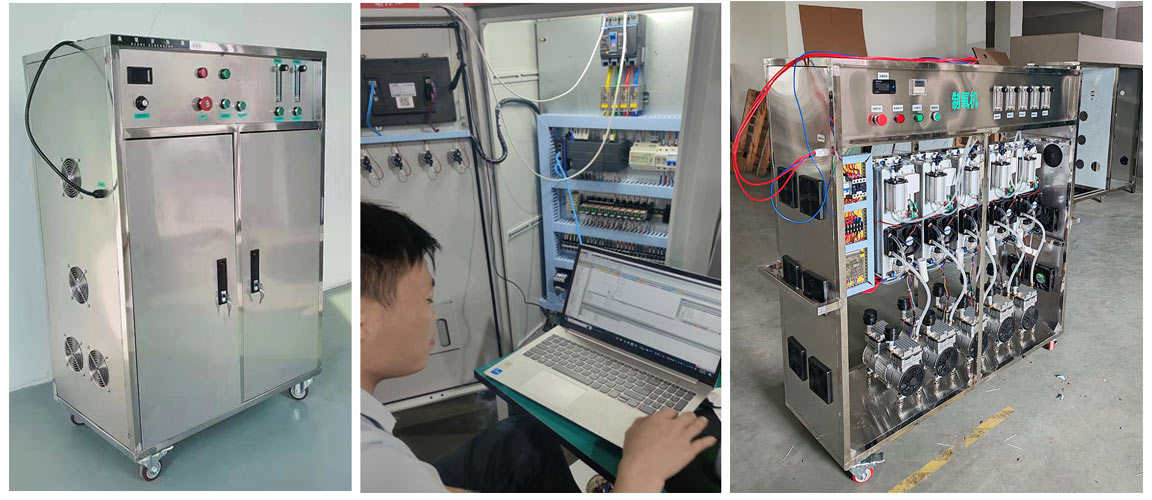

Industrial 50 liter oxygen generator Suppliers

High-quality lithium molecular sieve

Higher adsorption rate and better stability

Double-barrel molecular sieve filling and compression method, high density of circulating oxygen production, high oxygen concentration and more stable

High-efficiency oil-free air compressor, stable oxygen output 24 hours a day

Lower cost per unit of oxygen

By making oxygen on site, you will be able to set the exact purity required for your application without having to pay unnecessary fees for over-specified oxygen.

50L SLPM Oxygen generator machine 138 kPa 20 PSIG SPARE PARTS

1. Air Compressor (Screw type): Air is used as raw material to collect & compress air to 8 bar.

2. Refrigerated Dryer: The standard configuration removes moisture and impurities in the air, so that the air dew point reaches -20°C (the intermediate configuration uses an adsorption dryer, and the dew point reaches -40°C; the advanced configuration uses a combined dryer, and the dew point reaches- 60ºC).

3. Precision Filter: A/T/C three-stage filter to remove oil, dust and impurities.

4. Adsorption Tower: A&B adsorption tower can work alternately, regenerating adsorption, filling sodium molecular sieve to filter out oxygen molecules.

5. Oxygen Analyzer: real-time monitoring and analysis of oxygen purity, indicating that the equipment is working normally and alarming.

6. Valves & Pipelines: Intelligent control valves realize automatic operation of equipment, PLC control, SUS304 pipelines.

7. Oxygen Buffer Tank: Store oxygen with qualified purity, which can be directly piped or used for bottle filling.

Safety first

Thanks to the oxygen generator, there is no need to move pressurized gas cylinders.

Reduced footprint

Eliminate the need for oxygen transportation and delivery, reducing environmental footprint.

The use of oxygen (O2) spans many industries, from aquaculture to bioenergy to metallurgy and pharmaceuticals. In the past, companies could only get oxygen from suppliers. However, most companies now have a better option: on-site oxygen production. It enables professional oxygen users to make their own oxygen.

A reliable source of industrial gases is critical in many industries. On-site gas production equipment is a reliable source of nitrogen and oxygen. On-site gas production allows you to produce your own nitrogen or oxygen whenever you need it. Stop relying on third-party suppliers for your nitrogen or oxygen and produce it yourself with one of our gas generators. Our on-site gas generation offers a variety of benefits, from cost savings to continuous availability.

How an oxygen generator works: Pressure Swing Adsorption

The oxygen generator uses pressure swing adsorption (PSA) technology. The oxygen generator consists of two separate pressure vessels filled with Zeolite Molecular Sieve (ZMS) material to separate oxygen from the incoming air. At any one time, one of the vessels is producing oxygen while the other is "regenerating" its saturated ZMS.

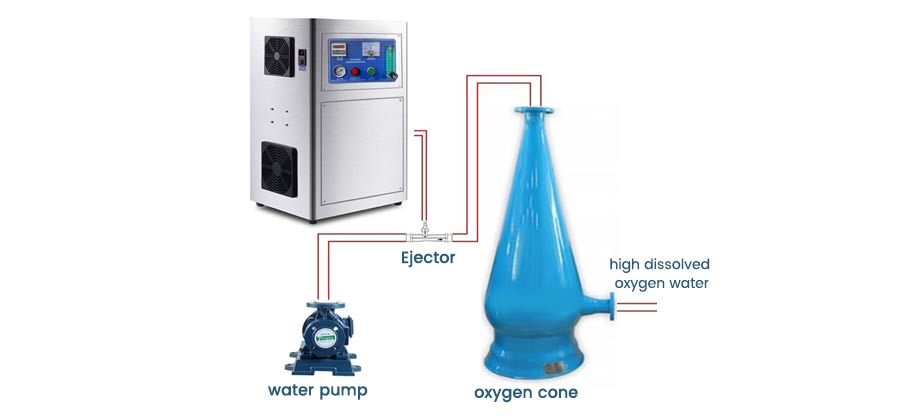

Aquaculture problems caused by the increase in dissolved oxygen

Oxygen is very important for aquaculture, especially for shrimp

1. Is the dissolved oxygen up to standard?

2.The fish is not moving, not energetic?

3.Always grow poorly, get a sick and die easily?

4.Slow reproduction, low yield?

Our 10 SLPM Oxygen generator machine 138 kPa 20 PSIG solves the above problems!

Send inquiry to get free sample and lowest factory price!

Do you have a design draft? What is the local normal temperature, humidity, and sea level? The more and more detailed the parameters provided, the more accurate the solution given

What equipment is required in the whole project? What equipment do you already have and what equipment do you need? What are the parameters of the existing equipment?

For the whole project, what kind of effect do you want to achieve? What needs to be corrected of the project? What are the third-party acceptance criteria?

What is your budget for the effect of the project? What equipment do we need to provide?

Inquiry