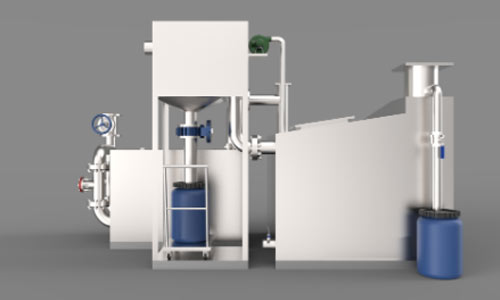

Triple separation: oil, water, and slag separation. The whole equipment is composed of three parts: solid-liquid separation device, oil-water separation device, and sewage lifting device.

■ Processing range: 1-100m3/h, two water pumps exchange operation.

■ Installation method: ground installation, pit installation, bracket installation.

■ Rated voltage: 380V

Features:

① Three-phase separation: three-phase separation of oil, water, and slag. The whole equipment is composed of three parts: a solid-liquid separation device, an oil-water separation device, and a sewage lifting device. Modular design, beautiful appearance, convenient installation, simple maintenance, and upgradeable capability.

② The solid-liquid separation device adopts a dual deslagging treatment system, and the large particles are transported to the slag collecting bucket outside the box through the automatic solid-liquid separation device for centralized treatment. Small particles of debris enter the sedimentation tank through the debris basket and discharge treatment regularly.

③ The inside of the equipment is designed with a polymer polymerization adsorption system, which forms tiny bubbles of 10μm-30μm. Under the action of the surface tension of the liquid, the halogenated oil molecular clusters are adsorbed on the bubbles and rise to the oil collection area, with antibacterial, self-closing, and soft exposure. Gas characteristics, high safety performance.

④ An ultra-stable water outflow device is designed between the oil-water separation device and the sewage lifting device, which has the function of stabilizing the liquid level, minimizing the influence of the amount of water on the entire system, and ensuring that the grease can flow out stably and continuously.

⑤ The oil-water separation device is equipped with a self-limiting temperature heating belt, and the outside is covered with a polymer constant temperature material to ensure that the oil is discharged smoothly in a liquid state.

⑥ There is an automatic purification system inside the equipment, and the sewage is purified by vortex, diffusion, volatilization, precipitation, and filtration inside the equipment.

⑦ The equipment is equipped with a sedimentation tank. Small debris and silt are deposited in the sedimentation tank. The gate is opened regularly, and the debris is washed into the slag collecting bucket for centralized cleaning.

⑧ The high-end configuration equipment is equipped with an oil purification device, which can further purify the grease.

⑨ Set up a sewage lifting device, which can forcibly discharge the treated sewage to a sump or septic tank.

Do you have a design draft? What is the local normal temperature, humidity, and sea level? The more and more detailed the parameters provided, the more accurate the solution given

What equipment is required in the whole project? What equipment do you already have and what equipment do you need? What are the parameters of the existing equipment?

For the whole project, what kind of effect do you want to achieve? What needs to be corrected of the project? What are the third-party acceptance criteria?

What is your budget for the effect of the project? What equipment do we need to provide?

Inquiry