Array

(

[id] => 4183

[site_id] => 1

[project_id] => 478

[cate_id] => 794

[thumb] => Array

(

[id] => 3917

[cate_id] => 1

[folder] => res/202507/02/

[name] => 75e275f67a6f29f6.png

[ext] => png

[filename] => res/202507/02/75e275f67a6f29f6.png

[ico] => res/_cache/_ico/39/3917.png

[addtime] => 1751447101

[title] => 124

[attr] => Array

(

[width] => 500

[height] => 400

)

[note] =>

[session_id] =>

[user_id] => 0

[download] => 0

[admin_id] => 1

[mime_type] => image/png

[gd] => Array

(

[auto] => res/_cache/auto/39/3917.png

[thumb] => res/_cache/thumb/39/3917.png

)

)

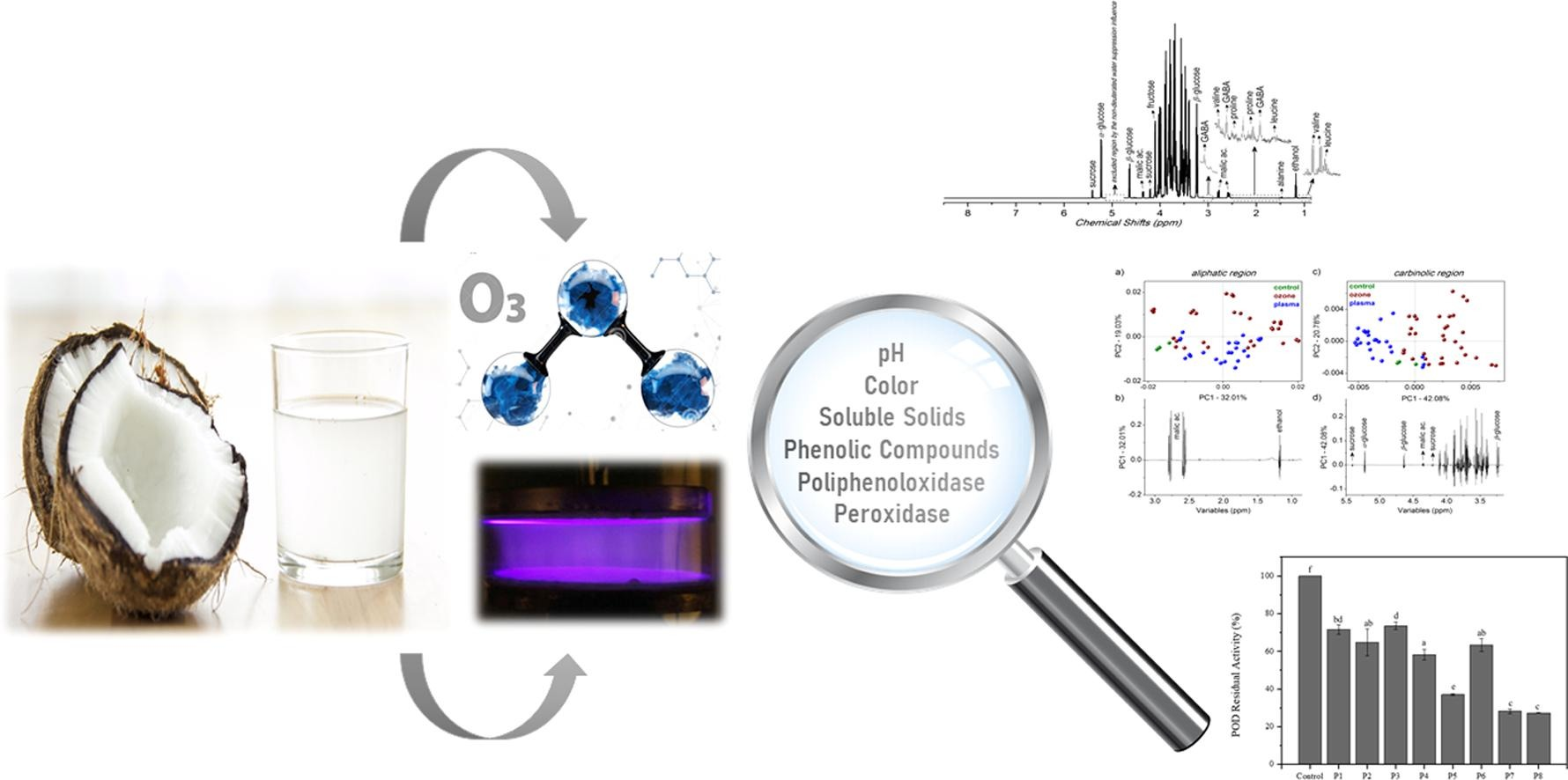

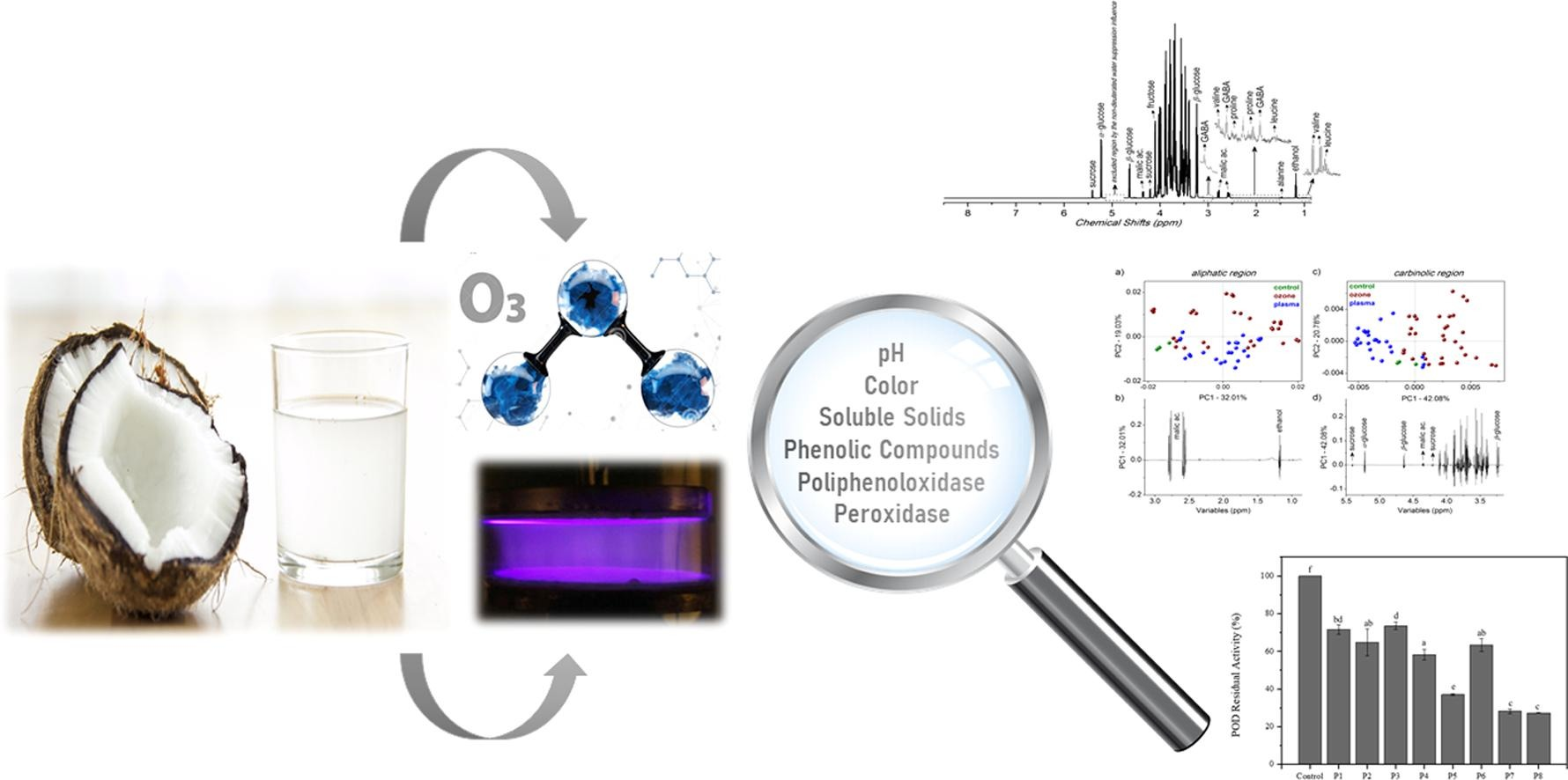

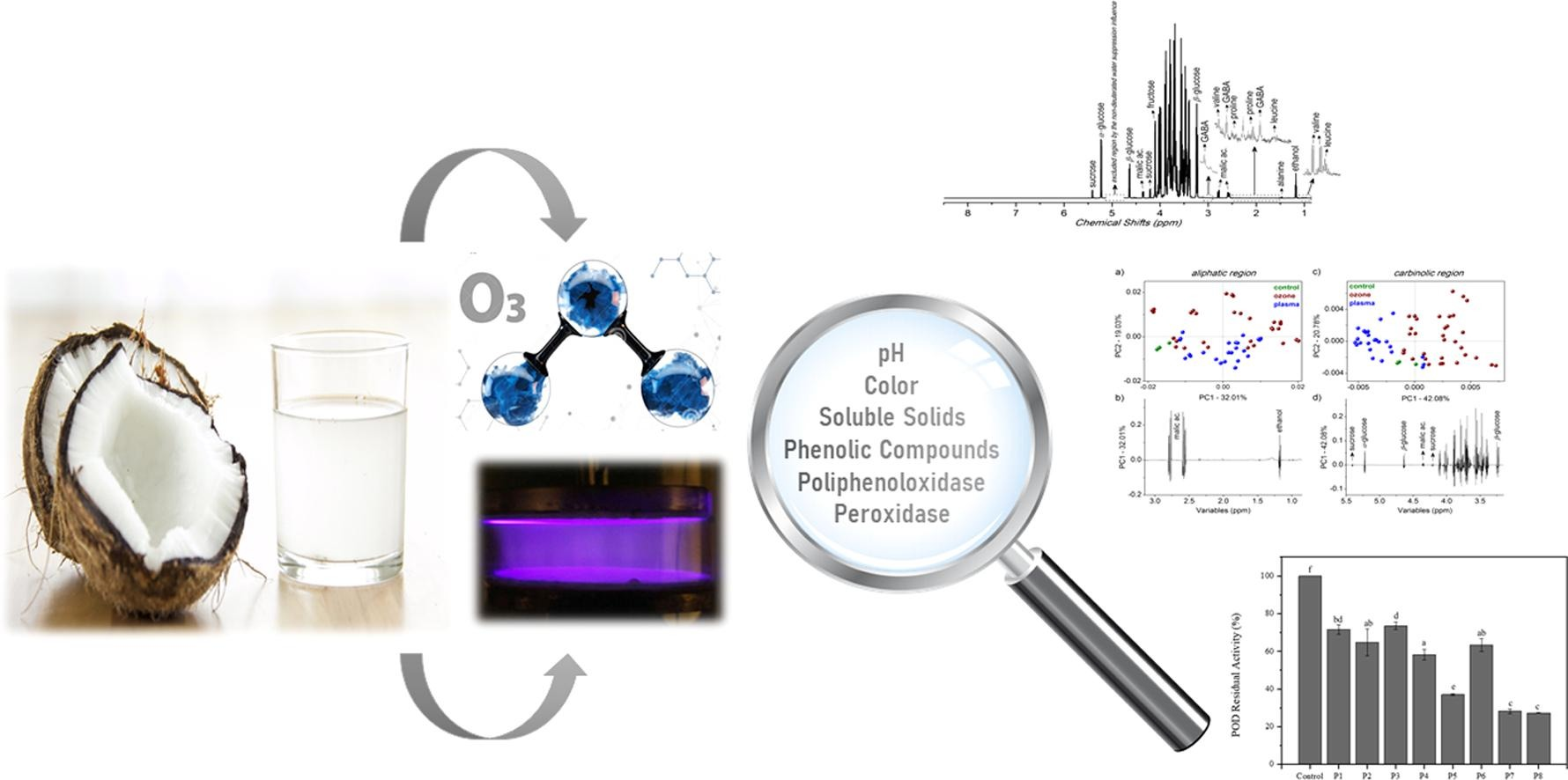

[content] => Ozone is primarily used in the food industry as a powerful, broad-spectrum disinfectant and sterilizing agent. Its applications focus on disinfecting production environments, sterilizing equipment and packaging materials, raw material washing, and treating certain liquid foods.

In coconut juice production, ozone can be applied in the following stages, but it is generally NOT used for direct treatment of the final packaged product:

-

Production Environment [**]ir Disinfection:

-

Purpose: To kill airborne bacteria, molds, yeasts, viruses, and other microorganisms; reduce airborne microbial counts; create an aseptic or clean production environment; prevent contamination of coconut juice before filling.

-

Method: Ozone generators produce ozone gas to fumigate key areas (e.g., filling rooms, blending areas) during non-production hours. [**]fter disinfection, sufficient time (typically >30 minutes) must be allowed for ozone to naturally decompose into oxygen and for ventilation before personnel re-enter.

-

Equipment, Pipeline, and Utensil Sterilization (CIP/SIP):

-

Purpose: To thoroughly sterilize equipment in direct contact with coconut juice (storage tanks, pipelines, fillers, valves, agitators), eliminating biofilms and residual microbes to prevent cross-contamination.

-

Method:

-

Ozonated Water Rinsing: High-concentration ozonated water (typically 1-4 ppm or higher) is used for circulating rinses or soaking equipment.

-

Ozone Gas Fumigation: Used for complex systems difficult to cover fully with liquid.

-

Packaging Material Sterilization:

-

Purpose: To sterilize bottles, caps, preforms, cap liners, Tetra Pak materials, etc., ensuring aseptic packaging.

-

Method:

-

Ozonated Water Soaking/Rinsing: Bottles, caps, etc., are soaked or vigorously rinsed in ozonated water.

-

Ozone Gas Treatment: Packaging materials pass through ozone gas tunnels before entering clean filling zones.

-

Raw Material (Coconut/Coconut Water) Pre-treatment (Limited Use):

-

Purpose: To wash/disinfect coconut shells (reducing contamination risk during opening) or reduce microbial load in initially extracted coconut water.

-

Method: Ozonated water washes coconut shells. For extracted coconut water, ozone gas or ozonated water can be briefly introduced. Critical controls include:

-

Concentration & Time: Precise control is essential for efficacy while avoiding over-oxidation.

-

Flavor & Nutrition: Ozone’s strong oxidation may degrade fats, proteins, vitamins (especially VC), and flavor compounds, causing color changes (e.g., yellowing), flavor deterioration (e.g., "metallic," "fishy" notes, loss of natural aroma), and reduced nutritional value.

-

Residual Removal: Treated coconut water must undergo degassing, settling, or aeration to ensure complete ozone decomposition (into oxygen) before further processing or filling.

-

Process Water/Sterile Water Preparation:

-

Purpose: To use ozone as a final sterilization barrier in water treatment systems for producing clean water (e.g., final rinse water, blending water).

-

Method: Ozone is dissolved into purified water (post-RO/filtration) to eliminate trace microbes.

Why is Ozone NOT Used Directly on Final Packaged Coconut Juice?

-

Strong Oxidation Damages Quality: Ozone causes irreversible oxidation of:

-

Unsaturated Fats: Leading to rancidity.

-

Proteins & [**]mino [**]cids: Generating off-flavors.

-

Vitamins (e.g., Vitamin C): Causing nutrient loss.

-

Pigments & Flavor Compounds: Resulting in color shifts (darkening/yellowing) and severe degradation of coconut juice’s characteristic fresh, sweet flavor, potentially creating off-odors (e.g., metallic, hay-like).

-

Residue Risk: Incomplete ozone decomposition leads to residual oxidation, accelerating quality decline and raising safety concerns.

-

Packaging Limitations: Technically challenging to evenly expose sealed packages to effective ozone concentrations; ozone water immersion is impractical post-packaging.

Summary:

Ozone’s core value in coconut juice production lies in sterilizing the environment, equipment, packaging, raw material surfaces, and process water to ensure a clean, low-microbial environment. Direct treatment of the final coconut juice product (pre- or post-filling) is strongly discouraged, as it severely compromises quality (flavor, color, nutrition) – the drawbacks far outweigh any benefits.

Common commercial sterilization methods for coconut juice include:

-

Ultra-High Temperature (UHT) Processing: The dominant method; brief high-temperature treatment (e.g., 135–140°C for seconds) followed by rapid cooling.

-

Retort Sterilization: For metal cans or glass bottles.

-

High-Pressure Processing (HPP): Non-thermal method preserving freshness; higher cost.

-

Sterile Filtration: For clear coconut water (cold sterilization).

Therefore, when addressing "how ozone is applied in coconut juice," the focus must be on its role in production hygiene control and the critical clarification that it is unsuitable for direct final product treatment.

[parent_id] => 0

[module_id] => 114

[title] => How Ozone is [**]pplied in Coconut Juice Production

[dateline] => 1751447216

[lastdate] => 1751447216

[sort] => 0

[status] => 1

[hidden] => 0

[hits] => 976

[tpl] =>

[seo_title] => How to use Ozone for food industry

[seo_keywords] => Ozone for food, ozone generator for food industry, ozone generator

[seo_desc] => Ozone is Applied in Coconut Juice Production

Ozone for food

ozone generator for food industry

ozone generator

[tag] => Array

(

[0] => Array

(

[id] => 110

[site_id] => 1

[identifier] =>

[title] => ozone generator system,Industrial ozone generator,ozone generator project

[url] => https://healthept.com/tag/110

[target] => _self

[hits] => 1757

[alt] => ozone generator system,Industrial ozone generator,ozone generator project

[is_global] => 0

[replace_count] => 0

[seo_title] =>

[seo_keywords] =>

[seo_desc] =>

[tpl] =>

[title_id] => c794

[html] =>

ozone generator system,Industrial ozone generator,ozone generator project

)

)

[attr] =>

[replydate] => 0

[user_id] => 0

[identifier] =>

[integral] => 0

[style] =>

[url] => https://healthept.com/4183.html

[_catelist] => Array

(

[794] => Array

(

[id] => 794

[site_id] => 1

[parent_id] => 736

[status] => 1

[title] => Industrial

[taxis] => 15

[tpl_list] =>

[tpl_content] =>

[psize] => 0

[seo_title] => Industrial ozone generator system project

[seo_keywords] => ozone generator system,Industrial ozone generator,ozone generator project

[seo_desc] => KQ Environmental Tech shares knowledge and useful articles onIndustrial ozone generator system project applications.The following is our case application, hope to provide you with valuable information.

[identifier] => Industrial

[tag] => ozone generator system,Industrial ozone generator,ozone generator project

[style] =>

[module_id] => 0

[psize_api] => 0

[url] => https://healthept.com/Case/Industrial.html

)

)

)

Ozone is primarily used in the food industry as a powerful, broad-spectrum disinfectant and sterilizing agent. Its applications focus on disinfecting production environments, sterilizing equipment and packaging materials, raw material washing, and treating certain liquid foods.

In coconut juice production, ozone can be applied in the following stages, but it is generally NOT used for direct treatment of the final packaged product:

-

Production Environment [**]ir Disinfection:

-

Purpose: To kill airborne bacteria, molds, yeasts, viruses, and other microorganisms; reduce airborne microbial counts; create an aseptic or clean production environment; prevent contamination of coconut juice before filling.

-

Method: Ozone generators produce ozone gas to fumigate key areas (e.g., filling rooms, blending areas) during non-production hours. [**]fter disinfection, sufficient time (typically >30 minutes) must be allowed for ozone to naturally decompose into oxygen and for ventilation before personnel re-enter.

-

Equipment, Pipeline, and Utensil Sterilization (CIP/SIP):

-

Purpose: To thoroughly sterilize equipment in direct contact with coconut juice (storage tanks, pipelines, fillers, valves, agitators), eliminating biofilms and residual microbes to prevent cross-contamination.

-

Method:

-

Ozonated Water Rinsing: High-concentration ozonated water (typically 1-4 ppm or higher) is used for circulating rinses or soaking equipment.

-

Ozone Gas Fumigation: Used for complex systems difficult to cover fully with liquid.

-

Packaging Material Sterilization:

-

Purpose: To sterilize bottles, caps, preforms, cap liners, Tetra Pak materials, etc., ensuring aseptic packaging.

-

Method:

-

Ozonated Water Soaking/Rinsing: Bottles, caps, etc., are soaked or vigorously rinsed in ozonated water.

-

Ozone Gas Treatment: Packaging materials pass through ozone gas tunnels before entering clean filling zones.

-

Raw Material (Coconut/Coconut Water) Pre-treatment (Limited Use):

-

Purpose: To wash/disinfect coconut shells (reducing contamination risk during opening) or reduce microbial load in initially extracted coconut water.

-

Method: Ozonated water washes coconut shells. For extracted coconut water, ozone gas or ozonated water can be briefly introduced. Critical controls include:

-

Concentration & Time: Precise control is essential for efficacy while avoiding over-oxidation.

-

Flavor & Nutrition: Ozone’s strong oxidation may degrade fats, proteins, vitamins (especially VC), and flavor compounds, causing color changes (e.g., yellowing), flavor deterioration (e.g., "metallic," "fishy" notes, loss of natural aroma), and reduced nutritional value.

-

Residual Removal: Treated coconut water must undergo degassing, settling, or aeration to ensure complete ozone decomposition (into oxygen) before further processing or filling.

-

Process Water/Sterile Water Preparation:

-

Purpose: To use ozone as a final sterilization barrier in water treatment systems for producing clean water (e.g., final rinse water, blending water).

-

Method: Ozone is dissolved into purified water (post-RO/filtration) to eliminate trace microbes.

Why is Ozone NOT Used Directly on Final Packaged Coconut Juice?

-

Strong Oxidation Damages Quality: Ozone causes irreversible oxidation of:

-

Unsaturated Fats: Leading to rancidity.

-

Proteins & [**]mino [**]cids: Generating off-flavors.

-

Vitamins (e.g., Vitamin C): Causing nutrient loss.

-

Pigments & Flavor Compounds: Resulting in color shifts (darkening/yellowing) and severe degradation of coconut juice’s characteristic fresh, sweet flavor, potentially creating off-odors (e.g., metallic, hay-like).

-

Residue Risk: Incomplete ozone decomposition leads to residual oxidation, accelerating quality decline and raising safety concerns.

-

Packaging Limitations: Technically challenging to evenly expose sealed packages to effective ozone concentrations; ozone water immersion is impractical post-packaging.

Summary:

Ozone’s core value in coconut juice production lies in sterilizing the environment, equipment, packaging, raw material surfaces, and process water to ensure a clean, low-microbial environment. Direct treatment of the final coconut juice product (pre- or post-filling) is strongly discouraged, as it severely compromises quality (flavor, color, nutrition) – the drawbacks far outweigh any benefits.

Common commercial sterilization methods for coconut juice include:

-

Ultra-High Temperature (UHT) Processing: The dominant method; brief high-temperature treatment (e.g., 135–140°C for seconds) followed by rapid cooling.

-

Retort Sterilization: For metal cans or glass bottles.

-

High-Pressure Processing (HPP): Non-thermal method preserving freshness; higher cost.

-

Sterile Filtration: For clear coconut water (cold sterilization).

Therefore, when addressing "how ozone is applied in coconut juice," the focus must be on its role in production hygiene control and the critical clarification that it is unsuitable for direct final product treatment.