- Killing adult insects and its eggs comparing to other chemicals which is not affective to killing the eggs .

- Bacteria Reduction of 75-80% using ozone compared to other chemicals [**]fter months of operation reduction of the Bacteria and harmful up to 95% in the field.

- Whitening process for flour ozone used as a bleaching agent .

- Ozone is not harmful comparing to other chemicals.

- Injection of ozone without stopping the operation process .

Reduce the cost of many process in one process only (injection the ozone to silos )

Greater than 20 ppm will achieve excellent reductions in pathogens for 30 seconds only

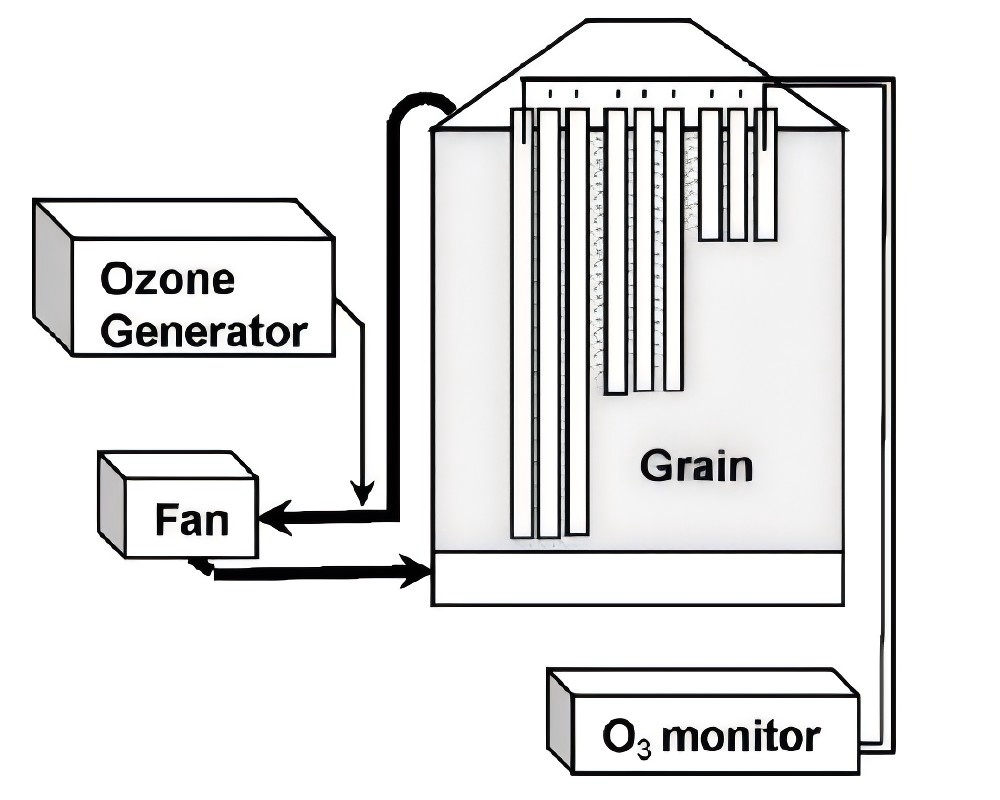

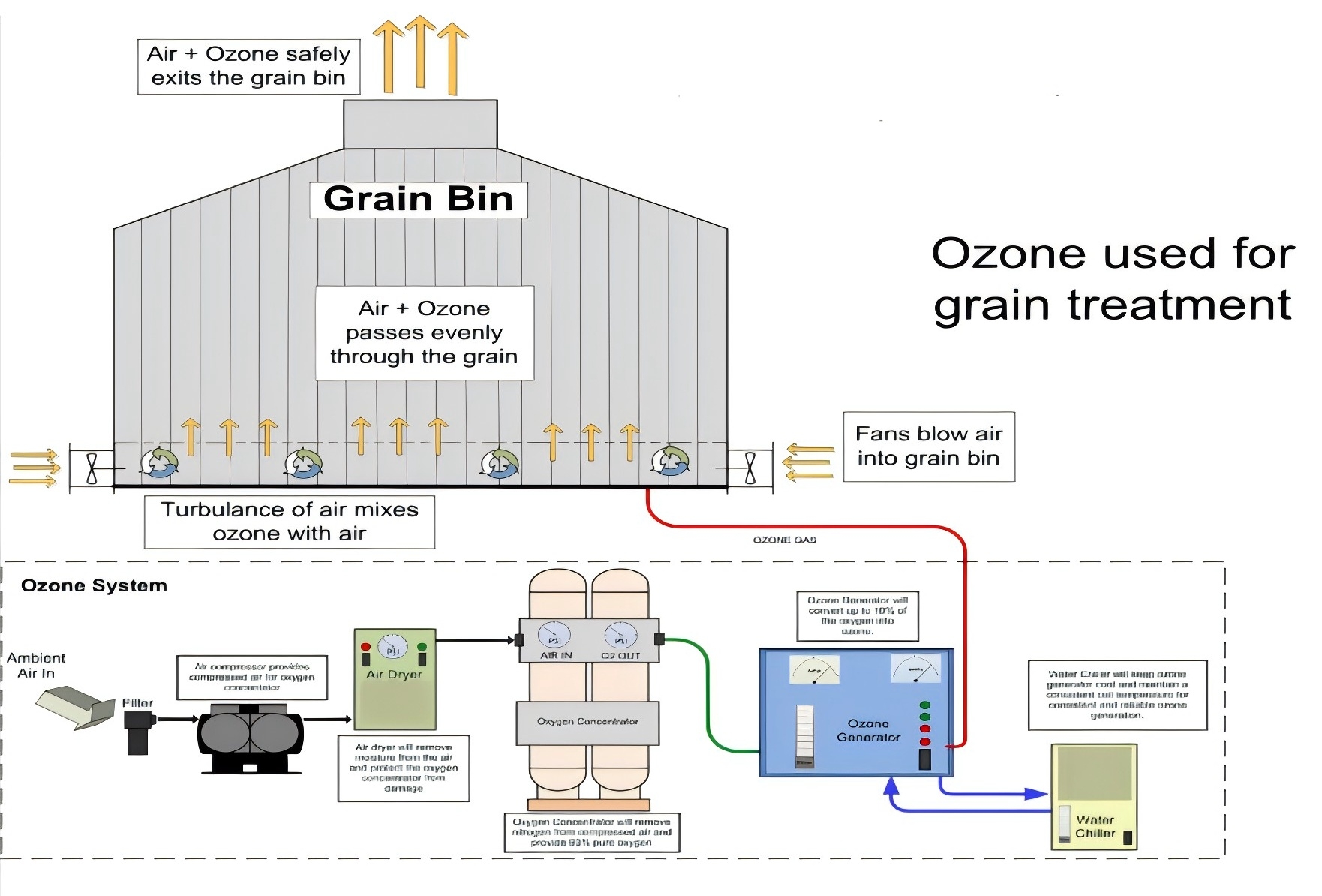

Ozone can be introduced into pneumatic or mechanical conveyors to disinfect grain in process. Conveyers that are used to transport milled grains from one location to another can be used to apply ozone gas to the grain. This is an efficient and convenient method of applying ozone gas to the grain.

Equipment can be sanitized by ozone gas disinfection.

Milling equipment can be sealed and exposed to high levels of ozone gas.

Ozone gas at effective levels for pathogen reduction can be used in these applications to safely reduce pathog ens without the use of chemicals or residuals.

Ozone gas requires more contact time and higher levels than aqueous ozone.

Ozone treatment eliminates harmful organisms

Ozone does not cause pest resistance like phosphine

Ozone is safer than the gases used, such as PH3

Ozone removes musty and burning smell, e.g. after grain ignition in a silo

Ozone is less harmful to grains than other gases

No hazardous gas transport is required because ozone is produced on site Ozone

decomposes spontaneously so there are no harmful residues

Inquiry